416 The SteriPen Revisited: Scaling UP! Your UV Digestion Knowledge

Release Date: 04/18/2025

458 Hiring Olympics and High-Performance Culture with J.D. Roth

458 Hiring Olympics and High-Performance Culture with J.D. Roth

Scaling UP! H2O

"Stay curious. And you only have one reputation. Guard it with your life." Hiring for judgment, not just rehearsed confidence Industrial water treatment is full of decisions made with incomplete data—on sites, with customers, and inside the business. (Managing Director and Co-owner of ) builds his hiring around that reality. His aim is straightforward: protect the team and the culture by selecting people who can think, collaborate, and lead under pressure. JD frames the organization as a group of people choosing to work toward a common goal: building a better future for...

info_outline 457 2026: A New Year with New Intentions

457 2026: A New Year with New Intentions

Scaling UP! H2O

Trace Blackmore opens 2026 with a practical reset: how to plan with urgency, sharpen the fundamentals that make troubleshooting easier, and use the tools around this podcast to keep your development moving all year. The 12-Week Year: urgency you can use Annual goals often feel “far away” until December forces focus. The 12-week year flips that dynamic by treating each quarter like a year—creating urgency sooner and giving you four chances to reset and improve. Trace walks through the structure: start with a vision (he uses a three-year example), then choose 3–5 tactical...

info_outline 456 The 12 Days of Scaling UP! H2O 2025

456 The 12 Days of Scaling UP! H2O 2025

Scaling UP! H2O

A year-end recap is more than a highlight reel—it’s a practical reset. In this New Year episode, Trace Blackmore walks through 2025 using a “12 Days of the Scaling Up Nation” format, tying together performance, community growth, listener engagement, and the sponsor support that keeps the podcast and its companion tools available at no cost. Year-end by the numbers Trace explains how he used to track every stat closely—and how that shifted into an unhealthy measure of self-worth—so the team now uses numbers as feedback, not validation. He notes the...

info_outline 455 Mentors, Mindset, and the CWT: Owning Your Water Career with Nella Fergusson

455 Mentors, Mindset, and the CWT: Owning Your Water Career with Nella Fergusson

Scaling UP! H2O

“So one thing I never do is try to start giving remediation or advice before I truly have understood and diagnosed the problem.” Mentorship and certifications don’t replace experience—but they can accelerate it when paired with the right mindset and a disciplined approach to learning. (District Manager, Southern California, ), lays out what “growing up” in industrial water treatment actually looks like: repeated exposure to real problems, strong diagnostic habits, and a willingness to keep learning long after year one. Learning that keeps...

info_outline 454 Water Recycling, Innovation, and Industry Wisdom with Dr. Kelle Zeiher

454 Water Recycling, Innovation, and Industry Wisdom with Dr. Kelle Zeiher

Scaling UP! H2O

Industrial cooling is one of the biggest levers industrial facilities can pull on water use—and it’s getting harder to ignore as data centers and other high-heat operations grow. Returning guest (Project Manager at ) breaks down what water reuse looks like when you move past slogans and into the realities of pretreatment, concentrate management, footprint, and cost. Cooling water reuse: the scale of the opportunity Dr. Zeiher reframes “drought” beyond rainfall, emphasizing aquifer recharge and the limits of focusing only on household restrictions. She...

info_outline 453 Water Risk, Governance, and Community Engagement with Dr. Annette Davison

453 Water Risk, Governance, and Community Engagement with Dr. Annette Davison

Scaling UP! H2O

Industrial water professionals sit at the intersection of risk, regulation, and community trust. In this episode, (“the water risk doctor”) joins Trace Blackmore to show how disciplined governance, clear supply chain thinking, and community engagement can turn fragmented water systems into coherent, defensible risk management frameworks. Water risk from source to customer Annette starts with a simple question most customers never ask: “Where’s your water coming from?” She walks through a conceptual supply chain from source to end point—collection, transfer, treatment,...

info_outline 452 UV Innovation and Whole-Building Water Safety with Ron Blutrich

452 UV Innovation and Whole-Building Water Safety with Ron Blutrich

Scaling UP! H2O

Entamoeba histolytica nearly ended Ron Blutrich’s scientific career. Instead, it pushed him to rethink how we protect people in multi-family buildings, senior facilities, and dense urban centers from invisible microbiological risks in their drinking water. In this episode, he joins host Trace Blackmore to unpack what whole-building UV can (and can’t) do for Legionella, biofilm, and real-world water safety. When One Bad Cup of Water Redefines a Career In the middle of his PhD in molecular genetics, Ron drank from an under-sink reverse osmosis tap at an Airbnb and...

info_outline 451 Building a Culture of Innovation and Customer Service with Frank Lecrone

451 Building a Culture of Innovation and Customer Service with Frank Lecrone

Scaling UP! H2O

What happens when you build a company around one niche, listen obsessively to customers, and never stop improving? In this episode, host Trace Blackmore finally sits down for a full-length conversation with , Founder, President, and CEO of . What started in a small 60' x 60' space in Hanover, Pennsylvania, with three employees, maxed-out credit cards, and endless Staples runs has grown into a 300+-person organization serving industrial water professionals around the world. Frank shares how AquaPhoenix became “the booth everyone wants to be next to” at...

info_outline 450 Wastewater Advocacy and Innovation with Robin Deal

450 Wastewater Advocacy and Innovation with Robin Deal

Scaling UP! H2O

“The More You Know” - Robin Deal A million-gallon-a-day perspective, distilled into actionable steps. , AquaPure Product Manager at unpacks how seasoned pros can squeeze more performance—and less sludge—out of industrial wastewater systems without compromising compliance or plant uptime. From “clear water in a jar” to stable discharge in the field Robin details a practical jar-testing workflow: start from upstream processes, target pH using hydroxide/sulfide solubility curves, choose the right coagulant (aluminum, iron, calcium, lanthanum, or organics),...

info_outline 449 Michael Bourgeois on AWT Partnerships and Professional Growth

449 Michael Bourgeois on AWT Partnerships and Professional Growth

Scaling UP! H2O

Get stuck in – Michael Bourgeois, CWT How do standards get written in ways that working water treaters can actually meet? In this conversation, AWT Past President, current Related Trade Organization (RTO) Committee Chair, and Chemco Products Company Operations Manager, , explains how AWT’s liaisons collaborate with peer organizations, so guidance reflects field reality—operations, risk, and achievable compliance. From Field Bags to Board Rooms: Why RTOs Matter Bourgeois outlines the purpose of AWT’s RTO structure: volunteer liaisons track and influence work at groups...

info_outline  “Always test your tools before field use. Side-by-side comparisons ensure repeatability and accuracy.”

“Always test your tools before field use. Side-by-side comparisons ensure repeatability and accuracy.”

In this episode of Scaling UP! H2O, host Trace Blackmore delivers an in-depth update on the SteriPen, a widely used tool for water treatment professionals. After overwhelming demand from listeners, we revisit the SteriPen, its capabilities, and its impact on testing organic phosphates and azoles. If you're looking for efficiency, precision, and portability in water testing, this episode is packed with actionable insights.

The Evolution of the SteriPen

Learn how the SteriPen became a game-changer in the industrial water treatment industry. Originally designed for hikers, it’s now widely adopted for phosphate digestion and azole testing.

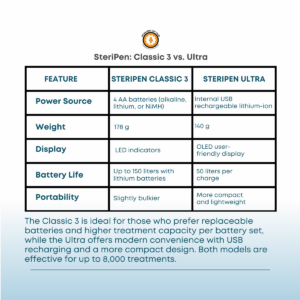

SteriPen Classic 3 vs. SteriPen Ultra: Which One Is Right for You?

SteriPen Classic 3 vs. SteriPen Ultra: Which One Is Right for You?

Trace compares the Classic 3 and Ultra models, discussing their battery life, efficiency, usability, and cost-effectiveness. Get clarity on which device suits your testing needs best.

Testing Efficiency: Reducing Time While Maintaining Accuracy

Find out how the SteriPen reduces testing time by half while maintaining accuracy, making it a must-have tool for water professionals.

Best Practices for SteriPen Use

From choosing the right vials and batteries to ensuring consistent testing results, this segment walks you through practical applications and expert recommendations.

The Future of Water Testing

How innovations like the SteriPen and other portable UV tools are reshaping the way industrial water treatment professionals conduct daily testing.

With water testing advancements, efficiency is key. Whether you're new to SteriPen or looking to upgrade, this episode provides valuable insights to optimize your water testing process.

Water professionals deserve better tools. Upgrade your phosphate and azole testing with the right SteriPen for maximum efficiency and accuracy.

Stay engaged, keep learning, and continue scaling up your knowledge!

Timestamps

02:28 – Trace Blackmore shares a recap of Episode 414

06:47 – Upcoming Events for Water Treatment Professionals

16:15 – Water You Know with James McDonald

20:45 – Deep dive into SteriPen device: it’s history and application

33:29 – Comparison between SteriPen Classic 3 and SteriPen Ultra

36:00 – Testing Procedures for organic and phosphate and azole tests

38:02 – Charging and battery life for both SteriPen models

Connect with Scaling UP! H2O

Submit a show idea: Submit a Show Idea

LinkedIn: in/traceblackmore/

YouTube: @ScalingUpH2O

Click HERE to download Episode’s Discussion Guide

Scaling UP! H2O Resources Mentioned

Ep 046 The One About Phosphate Testing

Ep 414 Pinks and Blues: Trace’s Phosphate Redux

Ep 415 Green Building Updates: What You Need to Know

Augmenting your testing procedures for Phosphonate and Azole testing

AWT (Association of Water Technologies)

Energizer Ultimate Lithium AA Batteries

Eowpower 30pcs 50ml Plastic Vial Storage Container

Hach Benzotriazole/Tolyltriazole

Hach Phosphonate

Lithium re-chargeable batteries

Re-chargeable Lithium Batteries with charger

Scaling UP! H2O Academy video courses

Steri Pen Classic 3

SteriPen Ultra

SteriPen Ultra – Katadyn Fact Sheet

Submit a Show Idea

The unboxing of everything you need to use the SteriPen in your

Phosphonate and Azole testing

Taylor Technologies Test Procedures: Phosphonate

Taylor Technologies Test Procedures: Azole

World Vision Global 6k for Water

Water You Know with James McDonald

Question: Does silica solubility typically decrease or increase with rising temperature?

2025 Events for Water Professionals

Check out our Scaling UP! H2O Events Calendar where we’ve listed every event Water Treaters should be aware of by clicking HERE.