462 From Lab Chemist to Field Mentor: Water, Culture, and Representation

Release Date: 02/06/2026

463 Mapping the Future of Water Innovation with Paul O’Callaghan

463 Mapping the Future of Water Innovation with Paul O’Callaghan

Scaling UP! H2O

“If you say something over and over often and enough, it becomes true because perception is reality.” has built a career at the intersection of water science, wastewater realities, and the practical question every operator and executive eventually faces; what actually moves innovation from idea to adoption. As Founder and CEO of, Paul explains how his team helps decision-makers put capital to work more efficiently in water by reducing uncertainty and separating signal from noise. He describes patterns he’s watched repeat across water entrepreneurs, pilots, and...

info_outline 462 From Lab Chemist to Field Mentor: Water, Culture, and Representation

462 From Lab Chemist to Field Mentor: Water, Culture, and Representation

Scaling UP! H2O

Industrial water work rewards people who can move between precision and practicality. brings both. She started as a lab chemist, then transitioned into field service with , where much of her work supports healthcare facilities and high-accountability programs. Lab habits that protect your tools and your data Katie describes the first surprise of field work: a central plant is “very dirty,” and the job demands good technique without chasing lab-level perfection. She shares a couple of simple practices that prevent expensive problems. Use proper lab wipes on...

info_outline 461 Corrosion, Lead, and Algae: New Tools for Old Water Problems

461 Corrosion, Lead, and Algae: New Tools for Old Water Problems

Scaling UP! H2O

Corrosion rarely announces itself as a “big water problem.” It shows up as leaching at the tap, residual loss in the field, premature equipment replacement, and the slow, expensive erosion of decision-quality. (CEO) and (chemist/Chief Science Officer) of lay out a system-wide view of corrosion control—starting with what changed in Flint from a technical standpoint and moving into why many utilities still struggle to meet expectations when standards and risk assumptions shift. System-wide corrosion control starts with chemistry...

info_outline 460 Building Boiler Talent: Fundamentals, Online Training, and Better Partnerships with Eric Johnson

460 Building Boiler Talent: Fundamentals, Online Training, and Better Partnerships with Eric Johnson

Scaling UP! H2O

Boilers can feel intimidating the first time you step into a boiler room—the heat, the noise, the pressure gauge, and the weight of knowing that mistakes can be costly. Trace Blackmore opens with a reminder that boilers deserve respect, not fear—and that learning fundamentals is how you replace mystique with clarity. The talent gap behind the boiler room door , Founder and CEO of , explains why boiler expertise is becoming harder to replace. He points to the shrinking pipeline of boiler-trained technicians—historically strengthened by Navy steam...

info_outline 459 From Wastewater to Resource: Water Reuse with Dr. Veronika Zhiteneva

459 From Wastewater to Resource: Water Reuse with Dr. Veronika Zhiteneva

Scaling UP! H2O

Industrial water professionals are increasingly pulled into conversations about scarcity, resilience, and “where the next gallon comes from.” , CEO and Co-founder of frames water reuse as an implementation challenge more than a technology gap—and explains where the practical starting points are when the scope feels overwhelming. Moving reuse forward when the technology already exists Waterloop Solutions was founded to accelerate implementation: clarifying end-use quality, identifying post-treatment needs on the back end of...

info_outline 458 Hiring Olympics and High-Performance Culture with J.D. Roth

458 Hiring Olympics and High-Performance Culture with J.D. Roth

Scaling UP! H2O

"Stay curious. And you only have one reputation. Guard it with your life." Hiring for judgment, not just rehearsed confidence Industrial water treatment is full of decisions made with incomplete data—on sites, with customers, and inside the business. (Managing Director and Co-owner of ) builds his hiring around that reality. His aim is straightforward: protect the team and the culture by selecting people who can think, collaborate, and lead under pressure. JD frames the organization as a group of people choosing to work toward a common goal: building a better future for...

info_outline 457 2026: A New Year with New Intentions

457 2026: A New Year with New Intentions

Scaling UP! H2O

Trace Blackmore opens 2026 with a practical reset: how to plan with urgency, sharpen the fundamentals that make troubleshooting easier, and use the tools around this podcast to keep your development moving all year. The 12-Week Year: urgency you can use Annual goals often feel “far away” until December forces focus. The 12-week year flips that dynamic by treating each quarter like a year—creating urgency sooner and giving you four chances to reset and improve. Trace walks through the structure: start with a vision (he uses a three-year example), then choose 3–5 tactical...

info_outline 456 The 12 Days of Scaling UP! H2O 2025

456 The 12 Days of Scaling UP! H2O 2025

Scaling UP! H2O

A year-end recap is more than a highlight reel—it’s a practical reset. In this New Year episode, Trace Blackmore walks through 2025 using a “12 Days of the Scaling Up Nation” format, tying together performance, community growth, listener engagement, and the sponsor support that keeps the podcast and its companion tools available at no cost. Year-end by the numbers Trace explains how he used to track every stat closely—and how that shifted into an unhealthy measure of self-worth—so the team now uses numbers as feedback, not validation. He notes the...

info_outline 455 Mentors, Mindset, and the CWT: Owning Your Water Career with Nella Fergusson

455 Mentors, Mindset, and the CWT: Owning Your Water Career with Nella Fergusson

Scaling UP! H2O

“So one thing I never do is try to start giving remediation or advice before I truly have understood and diagnosed the problem.” Mentorship and certifications don’t replace experience—but they can accelerate it when paired with the right mindset and a disciplined approach to learning. (District Manager, Southern California, ), lays out what “growing up” in industrial water treatment actually looks like: repeated exposure to real problems, strong diagnostic habits, and a willingness to keep learning long after year one. Learning that keeps...

info_outline 454 Water Recycling, Innovation, and Industry Wisdom with Dr. Kelle Zeiher

454 Water Recycling, Innovation, and Industry Wisdom with Dr. Kelle Zeiher

Scaling UP! H2O

Industrial cooling is one of the biggest levers industrial facilities can pull on water use—and it’s getting harder to ignore as data centers and other high-heat operations grow. Returning guest (Project Manager at ) breaks down what water reuse looks like when you move past slogans and into the realities of pretreatment, concentrate management, footprint, and cost. Cooling water reuse: the scale of the opportunity Dr. Zeiher reframes “drought” beyond rainfall, emphasizing aquifer recharge and the limits of focusing only on household restrictions. She...

info_outline

Industrial water work rewards people who can move between precision and practicality. Katie Holliday brings both. She started as a lab chemist, then transitioned into field service with Apex Water and Process, where much of her work supports healthcare facilities and high-accountability programs.

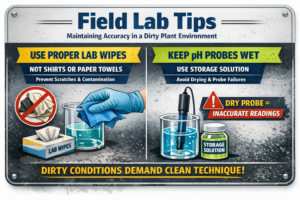

Lab habits that protect your tools and your data

Katie describes the first surprise of field work: a central plant is “very dirty,” and the job demands good technique without chasing lab-level perfection. She shares a couple of simple practices that prevent expensive problems. Use proper lab wipes on glassware instead of shirts or paper towels, which can scratch surfaces and compromise readings. Keep pH probes wet with the correct storage solution, because once they dry out, they often stop working.

Katie describes the first surprise of field work: a central plant is “very dirty,” and the job demands good technique without chasing lab-level perfection. She shares a couple of simple practices that prevent expensive problems. Use proper lab wipes on glassware instead of shirts or paper towels, which can scratch surfaces and compromise readings. Keep pH probes wet with the correct storage solution, because once they dry out, they often stop working.

Healthcare water: SPD work and Legionella prevention

About 90% of Katie’s accounts are healthcare. She defines SPD as the sterile processing department and explains why expectations shift compared to boilers and cooling towers. SPD work is cleaner, more controlled, and typically includes additional components such as endotoxin filtration and UV. It also involves more testing and stricter standards that tie directly to patient safety. Alongside SPD, she emphasizes Legionella prevention as a constant priority, from cooling towers (including secondary disinfection) to domestic water, because facilities want to reduce risk to patients.

Water chemistry reality check: Phoenix versus “everywhere else”

Katie explains how Arizona water changes the operating window. She notes high hardness and high chlorides, which can limit cycles of concentration and force conservative targets compared with places like Atlanta, where Trace describes running much higher cycles. The takeaway for experienced pros is familiar: operating limits are local, and “what good looks like” depends on the incoming water and the constraints that matter most at that site.

Mentorship, representation, and field readiness systems

Katie shares what it meant to be the first woman account manager hire in a long-running operation, and her advice is practical: recruit intentionally, then train people in the field, not from the sidelines. She credits her mentor, Bernie Peacock, for accelerating her learning curve, and she now passes that on by responding fast, following through, and providing steady backup to newer teammates. She also describes how she built mechanical confidence, using manuals, YouTube, phone video, and a OneNote playbook that captures account contacts, access details, sampling points, and “where things are” notes for clean coverage when someone else is on-site.

Listen to the full conversation above. Explore related episodes below. Stay engaged, keep learning, and continue scaling up your knowledge!

Timestamps

02:14 - Trace Blackmore shares “first day” intimidation and learning curve in water treatment

08:55 - Words of Water with James McDonald

12:30 - Upcoming Events for Water Treatment Professionals

14:48 - Interview begins: Katie Holliday introduced (Apex Water and Process)

15:55 – Lab to Field transition and technique

20:27 – Representation and Mentorship

26:42 – Culture and Water Stewardship

33:31 – Healthcare work, SPD, and Legionella

35:56 – Mentoring and “give it back”

39:22 – Mechanical Confidence, Tools, and Documentation Systems

Quotes and Key Takeaways

“What do I not know that I don’t know?”

“Everyone needs a Bernie Peacock”

“Field accuracy doesn’t require lab perfection, but it does require clean technique.”

“The most effective mentoring is responsive and practical.”

“Documentation scales your value”

Email: k.nativeamericanbeadwork@gmail.com

Website https://teamapex.com/

LinkedIn: https://www.linkedin.com/in/katie-holliday-9b6977246/

https://www.linkedin.com/company/apex-water-process/

Guest Resources Mentioned

The Perfect Marriage by Jeneva Rose

Under the Bridge by Rebecca Godfrey

AAMI ST108 Compliance in Sterile Processing

ASSE 12080 Legionella Water Safety certification

Scaling UP! H2O Resources Mentioned

AWT (Association of Water Technologies)

Scaling UP! H2O Academy video courses

Fearless Pricing: Ignite Your Team, Own Your Value, and Command What You Deserve by Casey Brown

Words of Water with James McDonald

Today's definition is the upward flow of water through a resin bed to clean, expand, and reclassify the bed. Can you guess the word?

2026 Events for Water Professionals

Check out our Scaling UP! H2O Events Calendar where we’ve listed every event Water Treaters should be aware of by clicking HERE.